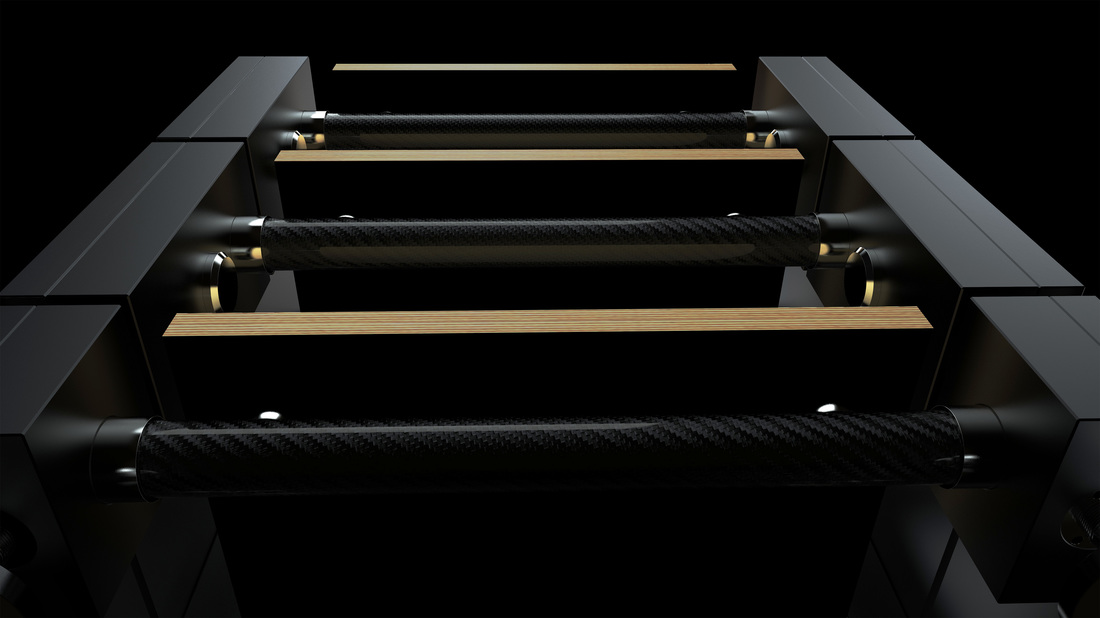

*A precision machined, advanced carbon fibre composite audio equipment rack providing optimal operational conditions for digital and analogue audio components.

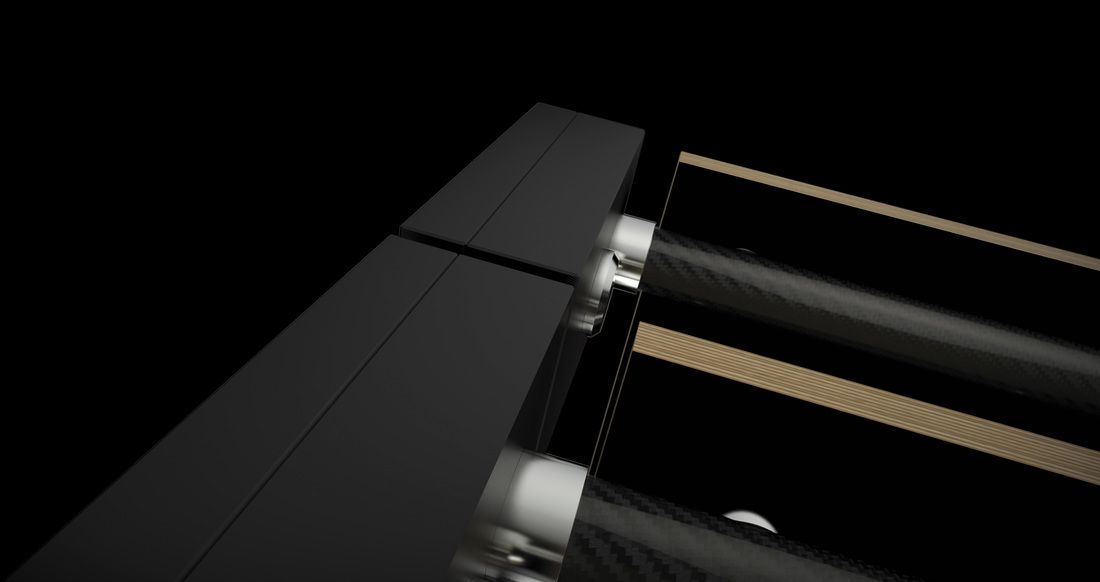

*Intrinsically self damping Polyoxymethylene vertical columns. Precision machined finish delivers exacting tolerances.

*The Carbon Fibre Isobar – an anisotropic super structure that incorporates a high tension internal compression bolt that exerts 14 tons per square inch of axial pressure on the carbon.

*The shelf to carbon interface is machined to provide optimal loading of the carbon fibre via off axis pinch point loading at 120 degrees.

*The management and control of structural borne vibration is critical in any audio structure. The R1 provides an elegant solution to a number of key concerns through clever engineering that is deceptively simple. The success of this design enables the R1 to be delivered fully assembled in tiers. Once the base tier is accurately referenced to the floor assembly takes a matter of minutes. Each tier is kinematically coupled by four precision ball bearings that are energy transfer nodes. Each of the four ball and sockets incorporate a low profile circumferential ring of visco elastic material that ensures the exact same mass loading at each Node.

*The Base Tier provides four, fully adjustable precision machined floor cups that were developed for the Cardinal. Each ball in each of these junctions sees 100 of tons of pressure at the interface ensuring optimal energy transfer to ground.

*The R1 is shipped fully assembled as single base and standard levels. the R1 is a modular design allowing any number of additional levels to be added according to the requirements of the system.